Changzhou Veidt Weighing Co., Ltd. © 2022 ALL RIGHTS RESERVED Privacy Policy | Calibration Weight | Test Weights | Cast Iron Weights | Standard Weights | Laboratory Weights

Product Category

Industrial Scale

Veidt Weighing is a Industrial Scale factory in china. In the complex ecosystem of modern industry, precision, efficiency, and reliability are the cornerstones of operational success. Among the myriad tools and equipment that underpin these principles, industrial scales stand out as unsung heroes. These devices, designed to measure the weight of raw materials, semi-finished products, and finished goods across a wide range of industrial settings, play a pivotal role in ensuring quality control, optimizing resource utilization, and maintaining seamless workflow. From the bustling floors of automotive factories to the vast warehouses of e-commerce giants, from chemical processing plants to agricultural distribution centers, industrial scales are indispensable components that bridge the gap between production processes and operational accountability.

1. The Fundamental Importance of Industrial Scales in Industrial Operations

At their core, industrial scales are more than just measuring instruments; they are critical enablers of operational efficiency and quality assurance. In any industrial process, the accurate measurement of weight directly impacts product consistency, cost control, and regulatory compliance (though specific certifications are not the focus here). For instance, in manufacturing, the precise mixing of raw materials is essential to producing products that meet predefined specifications. A slight deviation in the weight of a key component can compromise the integrity of the final product, leading to wasted resources, increased production costs, and even customer dissatisfaction. Industrial scales ensure that each batch of materials is measured with the required precision, minimizing variability and ensuring product uniformity.

Cost control is another area where industrial scales deliver significant value. Raw materials often represent a substantial portion of a company’s operational costs, and accurate weighing helps prevent overuse or underuse of these resources. By ensuring that only the necessary amount of material is used in each production cycle, businesses can reduce waste, lower procurement costs, and improve profit margins. Additionally, in logistics and shipping, accurate weight measurement is crucial for determining transportation costs. Most shipping carriers base their rates on the weight of the cargo, so precise weighing helps companies avoid overpaying for shipping or facing penalties for under-declaring weights.

Operational accountability is also enhanced by the use of industrial scales. By providing precise and verifiable weight data, scales enable businesses to track the flow of materials throughout the production and supply chain. This tracking capability helps identify bottlenecks in the workflow, monitor inventory levels, and ensure that materials are used efficiently. In industries where traceability is important, such as food processing or pharmaceuticals, weight data can be integrated into production records to provide a complete audit trail of each product’s journey from raw material to finished goods.

2. The Technical Evolution of Industrial Scales

The development of industrial scales has been driven by advances in technology and the growing demands of industrial operations. Early scales, such as mechanical balances and beam scales, relied on simple lever mechanisms to measure weight. While these devices were effective for basic weighing tasks, they lacked the precision, speed, and automation capabilities required for modern industrial processes. The introduction of electronic components in the mid-20th century marked a significant turning point in the evolution of industrial scales.

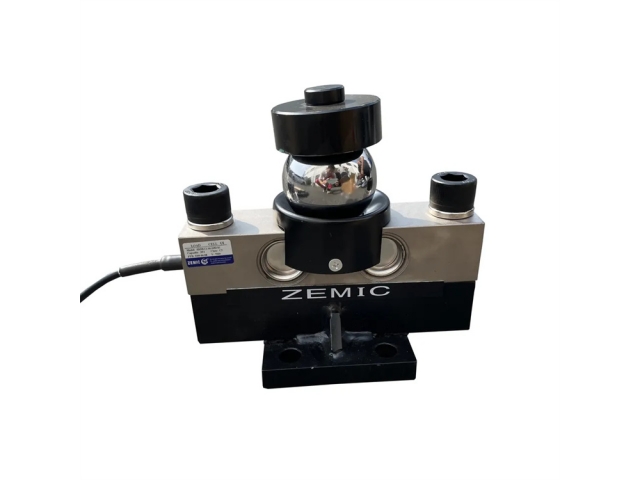

Electronic industrial scales, which use load cells to convert force (weight) into electrical signals, offer far greater precision and reliability than their mechanical predecessors. Load cells, which are typically made of metal alloys, deform slightly when a load is applied, and this deformation is detected by strain gauges attached to the load cell. The strain gauges convert the mechanical deformation into an electrical signal, which is then amplified and processed by a digital display unit to provide a precise weight reading. This technology has made it possible to measure weights ranging from a few grams to several tons with exceptional accuracy.

In recent decades, the integration of digital technology and software has further transformed industrial scales. Modern industrial scales are often equipped with digital displays, data logging capabilities, and connectivity features that allow them to integrate with other industrial systems, such as enterprise resource planning (ERP) software, manufacturing execution systems (MES), and warehouse management systems (WMS). This integration enables real-time data sharing, automated inventory updates, and remote monitoring of weighing processes. For example, in a warehouse, a digital industrial scale can automatically send weight data to a WMS, which then updates the inventory levels and generates shipping labels based on the measured weight.

Another significant technological advancement is the development of wireless industrial scales. These scales eliminate the need for cumbersome cables, making them ideal for use in large warehouses, outdoor facilities, or areas where cable installation is impractical. Wireless scales use Bluetooth, Wi-Fi, or other wireless communication protocols to transmit weight data to a central system, improving mobility and flexibility in industrial operations.

3. Diverse Types of Industrial Scales and Their Applications

Industrial scales come in a wide range of types, each designed to meet specific weighing requirements and operational needs. The selection of the right type of scale depends on factors such as the weight range of the items to be measured, the environment in which the scale will be used, the required level of precision, and the specific application. Below are some of the most common types of industrial scales and their typical applications.

3.1 Platform Scales

Platform scales are among the most versatile types of industrial scales, featuring a flat platform on which items are placed for weighing. They are available in a variety of sizes and weight capacities, ranging from small bench-top models capable of weighing up to 500 kg to large floor-mounted models that can handle weights of 10 tons or more. Platform scales are widely used in warehouses, distribution centers, and manufacturing facilities for weighing packages, boxes, and pallets. They are also commonly used in retail environments for weighing bulk items and in agricultural settings for weighing produce or livestock feed.

3.2 Crane Scales

Crane scales, also known as hanging scales, are designed to weigh heavy items that are suspended from a crane or hoist. They consist of a load cell enclosed in a protective housing, with a hook or shackle at the top for attaching to the crane and a hook at the bottom for lifting the load. Crane scales are ideal for weighing large, bulky items that cannot be easily placed on a platform scale, such as steel coils, machinery components, and shipping containers. They are commonly used in steel mills, ports, construction sites, and manufacturing facilities where heavy lifting and weighing are integral to the operation.

3.3 Bench Scales

Bench scales are compact, table-top scales that are designed for weighing smaller items with high precision. They typically have a weight capacity ranging from a few grams to 100 kg and are equipped with a digital display for easy reading. Bench scales are widely used in laboratories, pharmaceutical facilities, food processing plants, and small manufacturing operations for weighing raw materials, samples, and small components. Their compact size makes them ideal for use in areas where space is limited, and their high precision makes them suitable for applications where accurate measurement of small weights is critical.

3.4 Conveyor Scales

Conveyor scales are integrated into conveyor systems to weigh items as they move along the conveyor belt. They are designed for high-speed, continuous weighing applications and are commonly used in manufacturing facilities, distribution centers, and food processing plants. Conveyor scales eliminate the need to stop the production line to weigh items, thereby improving operational efficiency. They can be used to weigh individual items, such as packages or bottles, or to measure the total weight of a batch of materials as it moves along the conveyor. Conveyor scales are often used in conjunction with sorting systems to separate items based on weight.

3.5 Tank and Hopper Scales

Tank and hopper scales are designed to weigh the contents of tanks, hoppers, and silos. They consist of load cells that are mounted under the tank or hopper, which measure the weight of the container and its contents. Tank and hopper scales are widely used in chemical processing plants, food and beverage facilities, and agricultural operations for monitoring inventory levels of liquids, powders, and granular materials. They enable businesses to track the amount of material in storage, ensure that tanks are not overfilled, and accurately measure the amount of material used in production processes.

4. Key Considerations for Selecting and Maintaining Industrial Scales

Selecting the right industrial scale is a critical decision that can impact the efficiency, accuracy, and cost-effectiveness of industrial operations. There are several key factors that businesses should consider when choosing an industrial scale, including weight capacity, precision, environment, connectivity, and usability.

Weight capacity is the first and most important factor to consider. The scale must be capable of handling the maximum weight of the items that will be measured. Choosing a scale with a capacity that is too low can result in inaccurate readings or damage to the scale, while choosing a scale with a capacity that is too high can lead to unnecessary costs and reduced precision. It is important to select a scale with a capacity that is slightly higher than the maximum expected weight to ensure reliable performance.

Precision requirements vary depending on the application. For example, a laboratory scale used to weigh small samples may require a precision of 0.1 grams, while a platform scale used to weigh pallets may only require a precision of 1 kg. Businesses should carefully assess their precision needs and select a scale that meets or exceeds those requirements. It is also important to consider the repeatability of the scale, which is the ability to produce the same reading when weighing the same item multiple times.

The environment in which the scale will be used is another important consideration. Industrial scales may be exposed to a variety of harsh conditions, such as extreme temperatures, humidity, dust, vibration, and corrosive substances. Scales designed for use in these environments should be constructed from durable materials, such as stainless steel, and should be equipped with protective features, such as sealed load cells and waterproof displays. For example, a scale used in a food processing plant should be easy to clean and resistant to water and food acids, while a scale used in a construction site should be resistant to vibration and dust.

Connectivity features are becoming increasingly important in modern industrial operations. Scales with connectivity options, such as USB, Ethernet, Bluetooth, or Wi-Fi, can integrate with other systems, such as ERP or WMS software, to enable real-time data sharing and automation. This integration can improve operational efficiency, reduce manual data entry errors, and provide better visibility into the supply chain. Businesses should consider their data management needs and select a scale that offers the appropriate connectivity options.

Usability is another key factor to consider. The scale should be easy to operate, with a clear and intuitive display. It should also be easy to calibrate and maintain. Businesses should look for scales that come with user-friendly software and documentation, and that offer easy access to components for maintenance and repair.

Proper maintenance is essential to ensure the long-term performance and reliability of industrial scales. Regular maintenance can help prevent breakdowns, reduce downtime, and ensure accurate readings. Some key maintenance tasks include regular calibration, cleaning, inspection of load cells and other components, and software updates. Calibration is particularly important, as it ensures that the scale is measuring weight accurately. Calibration should be performed at regular intervals, depending on the frequency of use and the environment in which the scale is operated. Cleaning is also important, as dust, dirt, and other debris can accumulate on the scale and affect its performance. Load cells and other components should be inspected regularly for signs of wear or damage, and any damaged components should be replaced promptly. Software updates can help improve the functionality of digital scales and address any security vulnerabilities.

5. Emerging Trends Shaping the Future of Industrial Scales

The industrial scale industry is constantly evolving, driven by advances in technology and changing market demands. Several emerging trends are shaping the future of industrial scales, including the integration of Internet of Things (IoT) technology, the use of artificial intelligence (AI) and machine learning, and the development of more sustainable and energy-efficient scales.

The integration of IoT technology is one of the most significant trends in the industrial scale industry. IoT-enabled scales are equipped with sensors and connectivity features that allow them to collect and transmit real-time data to a central system. This data can be used to monitor the performance of the scale, track inventory levels, and optimize production processes. For example, IoT-enabled tank scales can send alerts when inventory levels are low, enabling businesses to reorder materials before they run out. IoT technology also enables predictive maintenance, as sensors can detect signs of wear or damage to the scale and alert maintenance teams before a breakdown occurs. This can help reduce downtime and improve the overall reliability of the scale.

The use of AI and machine learning is another emerging trend that is transforming the industrial scale industry. AI-powered scales can analyze large amounts of weight data to identify patterns and trends that would be difficult for humans to detect. For example, in a manufacturing facility, an AI-powered scale can analyze weight data from each production batch to identify variations in raw material usage, which can then be used to optimize the production process and reduce waste. AI can also be used to improve the accuracy of weighing by compensating for environmental factors, such as temperature and humidity, that can affect the performance of the scale. Machine learning algorithms can learn from past data to improve the precision and reliability of the scale over time.

Sustainability is also becoming an important consideration in the design and manufacture of industrial scales. Manufacturers are increasingly using eco-friendly materials, such as recycled steel, in the construction of scales. They are also developing more energy-efficient scales that consume less power, which can help reduce operating costs and minimize the environmental impact of industrial operations. Some scales are even equipped with solar panels, making them suitable for use in remote areas where access to electricity is limited.

Another trend is the development of more compact and portable industrial scales. As industrial operations become more flexible and mobile, there is a growing demand for scales that can be easily moved from one location to another. Portable scales are ideal for use in field operations, such as agricultural harvesting or construction sites, where a fixed scale is not practical. These scales are often lightweight, durable, and equipped with wireless connectivity features, making them easy to use and integrate into mobile workflows.

6. Conclusion

Industrial scales are essential components of modern industrial operations, playing a critical role in ensuring precision, efficiency, and accountability. From their humble mechanical origins to the advanced digital and IoT-enabled devices of today, industrial scales have evolved significantly to meet the growing demands of a rapidly changing industrial landscape. With a wide range of types available, there is an industrial scale to suit every application, from small laboratory weighing to heavy-duty industrial lifting and shipping.

Selecting the right industrial scale requires careful consideration of factors such as weight capacity, precision, environment, connectivity, and usability. Proper maintenance is also essential to ensure the long-term performance and reliability of the scale. As technology continues to advance, the future of industrial scales looks promising, with emerging trends such as IoT integration, AI and machine learning, sustainability, and portability set to further enhance their functionality and value.

In an increasingly competitive industrial environment, businesses that invest in high-quality, technologically advanced industrial scales will be better positioned to optimize their operations, reduce costs, and improve product quality. Industrial scales may not always be the most visible tools in the industrial ecosystem, but their impact on operational success is undeniable. As industry continues to evolve, industrial scales will remain a vital part of the infrastructure that drives global manufacturing, logistics, and supply chain operations.

Learn more about digital industrial scale, industrial weighing scale, heavy duty industrial scale, industrial platform scale, industrial floor scale, digital industrial weighing scale, industrial bench scale, industrial counting scale, industrial crane scale, industrial scale for warehouse, industrial scale for factory, high precision industrial scale, industrial scale for shipping, industrial scale with printer, industrial scale for logistics, industrial scale for manufacturing, industrial scale stainless steel, industrial scale for pallet weighing, industrial scale with bluetooth, industrial scale for construction, industrial scale for mining, industrial scale for agriculture, industrial scale for chemical industry, portable industrial scale, industrial scale for heavy load, industrial scale with lcd display, industrial scale for oil and gas, industrial scale auto-calibration, industrial scale for packaging line, industrial scale for metalworking, industrial scale for food processing, industrial scale with data logging, industrial scale for recycling, industrial scale for pharmaceutical, industrial scale explosion-proof, industrial scale battery operated, industrial scale usb rechargeable, industrial scale for textile industry, industrial scale for automotive industry, industrial scale with tare function, industrial scale backlight display, industrial scale for bulk material, industrial scale for laboratory, industrial scale easy to maintain, industrial scale for weighing containers, industrial scale durable, industrial scale for retail warehouse, industrial scale multi-functional, industrial scale for parts counting, pls contact us.