Changzhou Veidt Weighing Co., Ltd. © 2022 ALL RIGHTS RESERVED Privacy Policy | Calibration Weight | Test Weights | Cast Iron Weights | Standard Weights | Laboratory Weights

Product Category

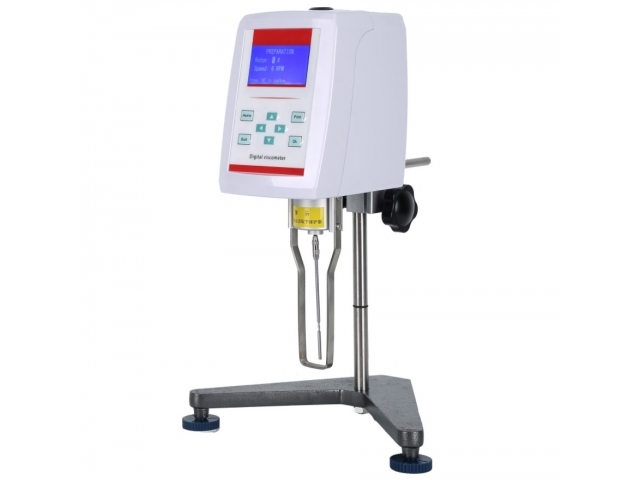

Digital Viscometer

Veidt Weighing is a Digital Viscometer factory in china. Digital viscometer is a precision electronic instrument used in contemporary laboratories and industrial fields to measure liquid viscosity, representing a digital revolution in traditional viscosity measurement techniques. This device, through advanced sensor and microprocessor technology, can quickly and accurately measure the viscosity characteristics of various fluids, and is widely used in the quality control and research and development fields of industries such as petrochemicals, food and beverage, pharmaceuticals, coatings, cosmetics, etc.

Modern digital viscometers are mainly based on the following three measurement principles:

Rotating measurement principle: The rotor is driven by a motor to rotate in a liquid, and the torque required to maintain a constant speed is measured. The magnitude of the torque is proportional to the viscosity of the liquid. The latest model adopts brushless motor and optical encoder, with a speed accuracy of ± 0.1%.

Principle of vibration measurement: Use piezoelectric crystals to vibrate the probe at a specific frequency, and calculate viscosity by measuring amplitude attenuation or frequency changes. This design is particularly suitable for online continuous monitoring and small sample size measurement.

Capillary digital system: Combining traditional capillary principles with high-precision pressure sensors and flow meters, viscosity is calculated by measuring the time it takes for a liquid to pass through a capillary at a certain pressure. It is commonly used for high-precision laboratory analysis.

The technical specifications of high-end digital viscometers include:

Measurement range: 0.1 mPa · s to 20000000 mPa · s (multi range models)

Temperature control accuracy: ± 0.01 ℃ (equipped with Peltier temperature control system)

Repeatability: ± 0.5% reading

Resolution: 0.01 mPa · s

Data transmission: standard USB/Bluetooth/Wi Fi, supports LIMS system docking

Innovative functional features

Intelligent temperature control system: a precision temperature control unit integrated with PID control algorithm, programmable temperature gradient testing function, meeting the requirements of ASTM D445 and other standards.

Multi parameter measurement: The new generation of equipment can synchronously measure rheological parameters such as viscosity, temperature, density, shear rate, and shear stress.

Adaptive calibration technology: using machine learning algorithms to automatically identify measurement status and adjust parameters in real-time to ensure optimal measurement accuracy.

Cloud data analysis platform: supports real-time uploading of measurement data to the cloud, providing trend analysis, batch comparison, and remote monitoring functions.

Industry application cases

Pharmaceutical industry: used for viscosity testing of injection solutions, stability research of biological agents, ensuring product consistency and injectability.

Petrochemical industry: quality monitoring of lubricating oil, fuel, asphalt and other products, multi-stage viscosity measurement to simulate different working conditions.

Food industry: analysis of rheological properties of non Newtonian fluids such as chocolate, sauces, dairy products, etc., and optimization of production processes.

In the field of 3D printing, viscosity temperature characteristics of printing materials such as photosensitive resins are measured to ensure the stability of the printing process.

Choosing a digital viscometer should consider:

Matching degree between measurement range and sample characteristics

Temperature control range and accuracy requirements

Data management and report generation functions

Daily maintenance points:

Regularly use standard oil for calibration verification

Clean the rotor promptly after use to avoid cross contamination

Avoid operating beyond the range or at inappropriate temperatures

Regularly update instrument firmware to obtain the latest features

With the advancement of materials science and microelectronics technology, digital viscometers will continue to make breakthroughs in accuracy, speed, and usability, providing more powerful fluid analysis solutions for various industries.

Learn more about rotational digital viscometer, portable digital viscometer, laboratory digital viscometer, digital viscometer calibration, brookfield digital viscometer, high precision digital viscometer, digital viscometer accuracy, digital viscometer for paint, digital viscometer price, digital viscometer maintenance, digital viscometer specification, industrial digital viscometer, digital viscometer accessories, digital viscometer calibration standard, digital viscometer for oil, digital viscometer software, digital viscometer sensitivity, digital viscometer verification, digital viscometer for food, digital viscometer calibration procedure, digital viscometer for cosmetics, digital viscometer error, digital viscometer for polymer, digital viscometer calibration service, digital viscometer user manual, digital viscometer for adhesive, digital viscometer parts, digital viscometer for chemicals, digital viscometer calibration frequency, digital viscometer for ink, digital viscometer calibration method, digital viscometer traceability, digital viscometer for pharmaceutical, digital viscometer calibration kit, digital viscometer for resin, digital viscometer calibration check, digital viscometer temperature control, digital viscometer for lubricant, digital viscometer calibration record, digital viscometer for battery slurry, digital viscometer repeatability test, digital viscometer for cement paste, digital viscometer anti-corrosion, digital viscometer for quality control, digital viscometer for biochemical samples, digital viscometer data logging, digital viscometer for pesticide, digital viscometer calibration verification standard, pls contact us.