Changzhou Veidt Weighing Co., Ltd. © 2022 ALL RIGHTS RESERVED Privacy Policy | Calibration Weight | Test Weights | Cast Iron Weights | Standard Weights | Laboratory Weights

Product Category

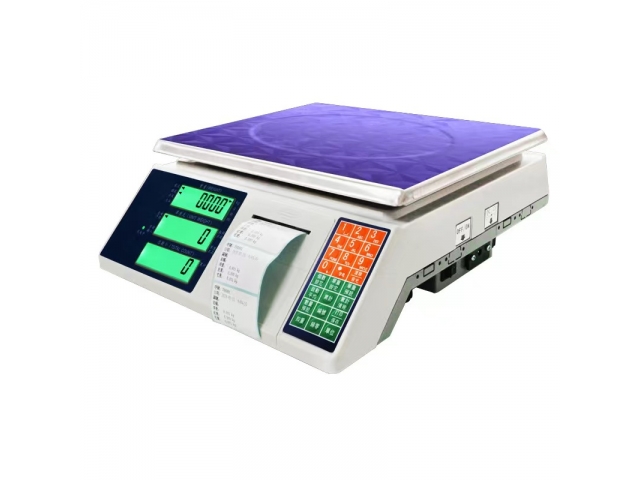

Printer Scale

Veidt Weighing is a Printer Scale factory in china. In the intricate web of modern commerce and industrial operations, efficiency and accuracy stand as irreplaceable pillars. Among the array of tools designed to uphold these principles, printing scales have emerged as unsung heroes, seamlessly integrating weight measurement with real-time documentation. Unlike conventional scales that merely display numerical values, printing scales bridge the gap between data collection and record-keeping, transforming raw weight data into actionable, tangible records. From the bustling checkout counters of neighborhood grocery stores to the precision-driven warehouses of global logistics firms, these devices have become indispensable, streamlining processes, reducing human error, and enhancing operational transparency.

To understand the value of printing scales, it is first essential to grasp their fundamental functionality. At their core, printing scales combine two primary components: a weighing system and a printing mechanism, unified by a central processing unit (CPU) that orchestrates data flow. The weighing system typically consists of load cells—sensors that convert mechanical force (from the weight of the object) into electrical signals. These signals are then transmitted to the CPU, which processes and converts them into readable weight values. What sets printing scales apart is their ability to take this processed data and immediately send it to the integrated printer, which generates a physical receipt, label, or ticket. Depending on the model, the printer may use thermal printing, dot matrix printing, or inkjet printing technologies, each suited to different environmental and operational needs. Thermal printers, for instance, are favored for their speed, quiet operation, and low maintenance, making them ideal for retail and food service settings, while dot matrix printers are valued for their durability and ability to print on multi-part forms, a necessity in some industrial and logistics applications.

Beyond their basic functionality, modern printing scales often incorporate additional features that enhance their versatility. Many models come equipped with digital displays for easy readability, programmable settings to accommodate different units of measurement (such as grams, kilograms, pounds, or ounces), and memory storage to retain recent measurements. Advanced versions may also include connectivity options, such as USB, Ethernet, or wireless capabilities, allowing them to sync data with point-of-sale (POS) systems, inventory management software, or cloud-based databases. This integration not only eliminates the need for manual data entry but also enables real-time tracking of inventory, sales, and shipping metrics, providing businesses with valuable insights to inform decision-making.

The advantages of printing scales extend far beyond mere convenience, offering tangible benefits that directly impact a business’s bottom line and operational efficiency. One of the most significant benefits is the reduction of human error. Manual recording of weight data—whether by writing down numbers or entering them into a computer—is prone to mistakes, such as transposition errors, misreadings, or omissions. These errors can lead to a host of problems, from incorrect pricing at the checkout to inaccurate shipping costs, inventory discrepancies, and even compliance issues in regulated industries. By automating the process of generating printed records, printing scales eliminate the human element from data transcription, ensuring that the weight information on the receipt or label is identical to the measured value. This accuracy not only improves customer satisfaction by preventing overcharging or undercharging but also enhances the reliability of business records, simplifying accounting and auditing processes.

Another key advantage is the streamlining of operational workflows. In environments where time is of the essence, such as busy retail stores or high-volume warehouses, every second counts. A printing scale allows a single operator to complete two tasks—weighing and documenting—in one step, eliminating the need to switch between a scale and a separate printer or computer. For example, in a deli, a cashier can weigh a customer’s order, generate a printed label with the weight, price, and item name, and attach it to the packaging in a matter of seconds. In a warehouse, a worker can weigh a package, print a shipping label with the weight and destination information, and prepare the package for dispatch without delay. This efficiency not only speeds up transaction times but also reduces labor costs, as fewer staff members are needed to complete routine tasks.

Printing scales also play a crucial role in enhancing traceability, a critical requirement in many industries. Traceability refers to the ability to track the movement of products or materials throughout the supply chain, from production to delivery. Printed records generated by printing scales serve as permanent documentation of weight measurements at various stages of the process, providing a clear audit trail. In the food industry, for instance, this traceability is essential for ensuring food safety, as it allows businesses to quickly identify and recall contaminated products by tracking their origin and distribution. In the pharmaceutical industry, accurate weight records are required to comply with good manufacturing practices (GMP), ensuring that medications are formulated with the correct ingredients in the right quantities. Even in retail, printed receipts with weight information provide customers with proof of purchase, facilitating returns and exchanges and building trust between the business and the consumer.

The versatility of printing scales is reflected in their wide range of applications across diverse industries. One of the most common uses is in the retail sector, particularly in grocery stores, delis, bakeries, and farmers’ markets. In these settings, products are often sold by weight, and customers require a printed receipt that clearly shows the weight, unit price, and total price. Printing scales in retail environments are typically compact, easy to use, and designed to handle a variety of products, from fresh produce to packaged meats. Many of these scales also offer customization options, allowing businesses to print their logo, contact information, or promotional messages on the receipt, enhancing brand visibility.

The logistics and shipping industry is another major user of printing scales. Shipping companies, courier services, and warehouses rely on printing scales to accurately measure the weight of packages, as shipping costs are often determined by weight and dimensions. A printing scale in this context can generate a shipping label that includes the package weight, tracking number, sender and recipient information, and barcode. This label not only ensures that the package is routed correctly but also allows for real-time tracking throughout the shipping process. Advanced printing scales in logistics may also integrate with shipping software, automatically calculating shipping costs based on the weight and destination, further streamlining the shipping process.

The food and beverage industry, beyond retail, also benefits greatly from printing scales. In food manufacturing facilities, printing scales are used to weigh ingredients during the production process, ensuring that each batch of product meets the required specifications. The printed records serve as proof of compliance with food safety regulations, such as those set by the Food and Drug Administration (FDA) in the United States or the European Food Safety Authority (EFSA) in Europe. In restaurants and catering businesses, printing scales can be used to portion food accurately, reducing waste and ensuring consistency in serving sizes. For example, a bakery can use a printing scale to weigh dough for each loaf of bread, ensuring that every loaf is the same size and weight, and print a record of each measurement for quality control purposes.

Industrial applications also leverage the capabilities of printing scales. In manufacturing plants, these scales are used to weigh raw materials, components, and finished products, providing accurate data for inventory management and quality assurance. For instance, in the automotive industry, printing scales may be used to weigh parts before assembly, ensuring that they meet the required weight specifications and preventing defective parts from entering the production line. In the construction industry, printing scales can be used to weigh materials such as cement, sand, and gravel, ensuring that the correct quantities are used in each project and providing a record for cost accounting.

When selecting a printing scale, businesses must consider several key factors to ensure that the device meets their specific needs. The first factor is the weight capacity of the scale. Different applications require different weight ranges—for example, a retail deli may only need a scale with a capacity of 10 kilograms, while a warehouse shipping heavy packages may require a scale with a capacity of 100 kilograms or more. It is important to choose a scale with a capacity that exceeds the maximum weight of the items to be measured, as overloading the scale can lead to inaccurate readings and damage to the device.

Accuracy is another critical consideration. The level of accuracy required depends on the application—for example, pharmaceutical manufacturing requires extremely high accuracy, while weighing large packages for shipping may tolerate a slightly lower level of precision. Printing scales are typically rated by their readability, which is the smallest unit of measurement that the scale can detect. For example, a scale with a readability of 1 gram can measure differences of 1 gram, making it suitable for applications that require precise measurements. Businesses should also consider the calibration requirements of the scale, as regular calibration is necessary to maintain accuracy over time.

The type of printer integrated into the scale is also an important factor. As mentioned earlier, thermal printers are ideal for retail and food service settings due to their speed and low maintenance, but they require thermal paper, which can be more expensive than standard paper. Dot matrix printers are more durable and can print on multi-part forms, making them suitable for industrial and logistics applications, but they are slower and noisier than thermal printers. Inkjet printers offer high-quality printing but are less common in printing scales due to their higher cost and maintenance requirements. Businesses should choose a printer type that aligns with their operational needs and budget.

Connectivity options are another consideration for modern businesses. Many printing scales now offer USB, Ethernet, or wireless connectivity, allowing them to integrate with POS systems, inventory management software, or cloud-based platforms. This integration enables real-time data sharing, eliminating the need for manual data entry and providing businesses with up-to-date information on sales, inventory, and shipping. Businesses that rely on digital record-keeping or need to access data remotely should prioritize scales with advanced connectivity features.

Environmental factors, such as the operating temperature, humidity, and presence of dust or moisture, should also be taken into account. For example, a printing scale used in a cold storage facility must be able to operate reliably at low temperatures, while a scale used in a bakery must be resistant to heat and moisture. Choosing a scale that is designed to withstand the specific environmental conditions of the workplace will ensure durability and long-term performance.

Looking to the future, printing scales are poised to undergo further evolution, driven by advancements in technology and changing business needs. One of the key trends shaping the future of printing scales is the integration of Internet of Things (IoT) technology. IoT-enabled printing scales can connect to a network of devices and systems, allowing for remote monitoring and control. For example, a business owner can access real-time weight data and printer status from a mobile device or computer, enabling proactive maintenance and troubleshooting. IoT integration also enables predictive analytics, as the scale can collect and analyze data over time to identify patterns and trends, such as peak weighing times or frequent maintenance issues, helping businesses optimize their operations.

Another emerging trend is the adoption of wireless and portable printing scales. As businesses become more mobile and flexible, there is a growing demand for scales that can be used in different locations without the need for a power cord or wired connection. Portable printing scales, powered by rechargeable batteries and equipped with wireless connectivity, are ideal for farmers’ markets, food trucks, and mobile shipping services. These scales offer the same level of accuracy and functionality as stationary models but with the added convenience of mobility.

Advancements in printing technology are also expected to enhance the capabilities of printing scales. For example, the development of more efficient thermal printing technology may reduce the cost of thermal paper and extend the lifespan of print heads, making thermal printers even more cost-effective for businesses. Additionally, the integration of color printing capabilities may allow printing scales to generate more informative and visually appealing receipts and labels, including product images, barcodes, and QR codes that link to additional product information or promotional offers.

Data security is another area that will receive increased attention in the future of printing scales. As these devices become more connected to digital systems, the risk of data breaches and cyberattacks increases. Manufacturers will need to implement robust security measures, such as encryption, authentication, and secure data storage, to protect sensitive information, such as customer data, sales records, and inventory details. Businesses, in turn, will need to prioritize scales that meet industry-specific security standards to ensure compliance with data protection regulations.

In conclusion, printing scales have evolved from simple weighing devices to essential tools that drive efficiency, accuracy, and traceability in modern business operations. Their ability to integrate weight measurement with real-time documentation makes them invaluable across a wide range of industries, from retail and logistics to food manufacturing and industrial production. When selecting a printing scale, businesses must consider factors such as weight capacity, accuracy, printer type, connectivity, and environmental resistance to ensure that the device meets their specific needs. As technology continues to advance, printing scales will become even more versatile and intelligent, with IoT integration, portability, and enhanced printing capabilities shaping their future. In an increasingly fast-paced and data-driven business landscape, printing scales will remain a critical component of operational success, helping businesses stay competitive by streamlining processes, reducing errors, and improving transparency.

Learn more about digital printer scale, scale with printer, commercial printer scale, weighing scale with printer, pos scale with printer, label printer scale, receipt printer scale, digital weighing scale with printer, commercial weighing scale with printer, cash register scale with printer, platform scale with printer, bench scale with printer, shipping scale with printer, retail scale with printer, label printing scale, receipt printing scale, industrial printer scale, heavy duty printer scale, digital platform scale with printer, digital bench scale with printer, grocery store scale with printer, supermarket scale with printer, barcode printer scale, usb printer scale, bluetooth printer scale, portable printer scale, food scale with printer, commercial label printer scale, warehouse scale with printer, logistics scale with printer, package scale with printer, printer scale for retail, printer scale for grocery, printer scale for shipping, printer scale for warehouse, digital label printer scale, electronic printer scale, printer scale with lcd display, high precision printer scale, printer scale with thermal printer, butcher shop scale with printer, bakery scale with printer, deli scale with printer, farmers market scale with printer, printer scale with auto-calibration, printer scale stainless steel, multi-function printer scale, printer scale for small business, printer scale with weight and price print, pls contact us.