Changzhou Veidt Weighing Co., Ltd. © 2022 ALL RIGHTS RESERVED Privacy Policy | Calibration Weight | Test Weights | Cast Iron Weights | Standard Weights | Laboratory Weights

Product Category

Accessory

In the realm of industrial production, logistics and transportation, scientific research, and daily life services, accurate weight measurement serves as a fundamental pillar supporting operational efficiency, quality control, and transaction fairness. Behind every precise weight reading lies a well-coordinated system composed of several key components, each undertaking unique and indispensable roles. Among these, the Weighing Indicator, Load Cell, Junction Box, and Weighing Printer stand out as the core elements that form the backbone of modern weighing systems. From converting mechanical force into electrical signals to processing data, transmitting information, and generating permanent records, these four components work in tandem to realize the full functionality of weight measurement.

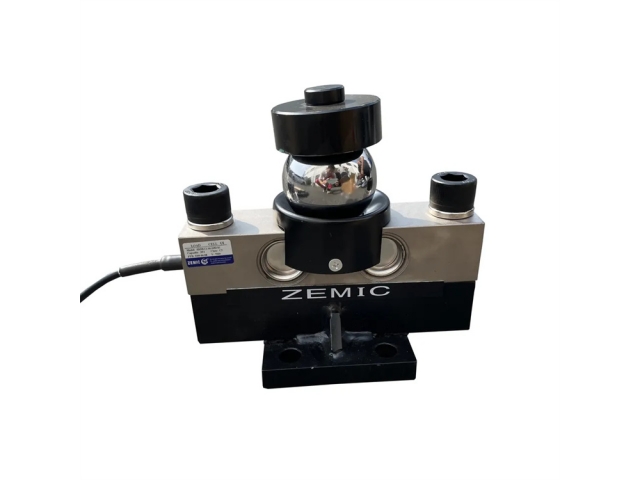

The Load Cell, often hailed as the "sensing heart" of a weighing system, is the component responsible for converting the physical quantity of weight into a measurable electrical signal. Unlike traditional mechanical sensing elements, modern Load Cells leverage advanced electrical measurement principles to achieve high precision and stability, making them the cornerstone of accurate weight measurement. The working principle of a Load Cell is based on the piezoelectric effect, strain gauge effect, or capacitance effect, among which the strain gauge Load Cell is the most widely used in industrial and commercial applications. A typical strain gauge Load Cell consists of an elastic body (usually made of high-strength alloy materials such as stainless steel or aluminum alloy) and several strain gauges bonded to the elastic body. When a load (weight) is applied to the elastic body, it undergoes a slight elastic deformation that is proportional to the load. This deformation causes a change in the resistance of the strain gauges, which are connected in a Wheatstone bridge circuit. The change in resistance disrupts the balance of the Wheatstone bridge, resulting in a small electrical signal (usually in millivolts) that is proportional to the applied load. It is this electrical signal that serves as the raw data for subsequent weight measurement.

The performance of a Load Cell directly determines the overall accuracy and reliability of the weighing system. Key performance indicators include measurement range, accuracy class, sensitivity, temperature stability, and long-term reliability. For example, in high-precision applications such as pharmaceutical production and gold refining, Load Cells with an accuracy class of 0.01 or higher are required to ensure that the weight error is within an acceptable range. In contrast, in rough industrial environments such as construction sites, Load Cells need to have strong resistance to shock, vibration, and harsh weather conditions, even if the accuracy class is relatively lower. Additionally, the material selection of the elastic body is crucial: stainless steel elastic bodies are preferred in corrosive environments such as chemical plants, while aluminum alloy elastic bodies are used in light-load applications due to their lightweight and cost-effectiveness. The diversity of Load Cell types—including beam-type, column-type, shear-beam-type, and tension-type—allows them to be adapted to different weighing scenarios, such as platform scales, hopper scales, crane scales, and belt scales.

While the Load Cell generates the electrical signal corresponding to the weight, this signal is typically weak and cannot be directly used for display or data processing. This is where the Weighing Indicator comes into play, acting as the "brain" of the weighing system that processes, amplifies, and displays the weight information. The Weighing Indicator, also known as a weight indicator or weighing controller, is an electronic device that receives the millivolt-level signal from the Load Cell, performs a series of signal processing operations, and converts it into a readable weight value. The core functions of a Weighing Indicator include signal amplification, filtering, analog-to-digital (A/D) conversion, data calibration, and display output. The weak electrical signal from the Load Cell first passes through a high-precision amplifier to enhance its amplitude, then through a filter circuit to eliminate interference signals (such as electrical noise from the industrial environment), ensuring the purity of the signal. Subsequently, the analog signal is converted into a digital signal by an A/D converter, which can be processed by the indicator's microprocessor.

The microprocessor is the core component of the Weighing Indicator, responsible for executing data processing algorithms, performing zero adjustment, tare adjustment, and weight calibration, and converting the digital signal into a weight value displayed on the screen (usually an LCD or LED display). In addition to basic display functions, modern Weighing Indicators often integrate advanced features to meet diverse application needs. For example, they may have data storage capabilities to record historical weighing data, communication interfaces (such as RS232, RS485, Ethernet, or USB) to transmit data to computers, PLCs, or other control systems, and programmable functions to adapt to specific weighing processes (such as automatic batching, filling, or sorting). Some high-end Weighing Indicators also support multi-unit conversion (e.g., kilograms, pounds, tons) and have built-in diagnostic functions to monitor the working status of the Load Cell and the indicator itself, providing timely alerts for faults such as signal loss or overload.

In many weighing systems, especially large-scale weighing equipment such as truck scales, rail scales, or large hopper scales, a single Load Cell is often insufficient to meet the requirements of load-bearing capacity and measurement accuracy. Instead, multiple Load Cells are used in parallel to distribute the load evenly and improve the stability of the measurement. In such cases, the Junction Box serves as the "signal hub" that connects multiple Load Cells to the Weighing Indicator, realizing signal convergence, adjustment, and transmission. The primary function of the Junction Box is to collect the electrical signals from each Load Cell, adjust the signal output of each Load Cell to ensure consistency (a process known as "matching"), and then transmit the combined signal to the Weighing Indicator. This signal matching is crucial because even Load Cells of the same model may have slight differences in sensitivity due to manufacturing tolerances. If these differences are not adjusted, the measurement accuracy of the entire system will be affected.

A typical Junction Box is equipped with terminal blocks for connecting the signal wires of each Load Cell, as well as potentiometers (adjustment resistors) for adjusting the sensitivity of each Load Cell. During the installation and calibration of the weighing system, technicians can adjust the potentiometers to ensure that each Load Cell outputs the same signal amplitude under the same load, thereby ensuring the uniformity and accuracy of the overall measurement. In addition to signal convergence and adjustment, the Junction Box also provides protection for the signal lines. It is usually designed with a sealed and waterproof housing, which can prevent dust, moisture, and corrosive substances from entering, protecting the internal electrical components and ensuring stable signal transmission in harsh industrial environments. Some advanced Junction Boxes also have signal filtering functions to further reduce electrical interference, and may be equipped with status indicators to show whether each Load Cell is working normally, facilitating fault diagnosis.

After the Weighing Indicator processes the weight data and displays the result, in many application scenarios, there is a need to generate a permanent physical record of the weighing result for purposes such as transaction verification, quality inspection, inventory management, and traceability. This is the role of the Weighing Printer, which acts as the "documentation tool" of the weighing system, converting the digital weight data into a printed document. The Weighing Printer is usually connected to the Weighing Indicator via a communication interface (such as RS232, USB, or Bluetooth) and can print the weight value, weighing time, serial number, and other relevant information on paper or labels according to pre-set formats.

The types of Weighing Printers vary according to the application scenario and printing requirements. Common types include thermal printers, dot matrix printers, and label printers. Thermal printers are widely used in commercial and light industrial environments due to their fast printing speed, low noise, and low maintenance cost (no need for ink, only thermal paper). Dot matrix printers, on the other hand, are more suitable for harsh industrial environments with high temperature, humidity, or dust, as they have strong durability and can print on ordinary paper. Label printers are used in scenarios where weighing results need to be attached to products or packages, such as logistics and warehousing, allowing for easy labeling and tracking. In addition to basic printing functions, modern Weighing Printers can also support customized printing formats. Users can set the content to be printed (such as company name, product code, batch number) according to their needs, and some printers can even integrate barcode or QR code printing functions, enabling the weighing data to be quickly scanned and entered into the management system, improving the efficiency of data management and traceability.

The four core components—Load Cell, Weighing Indicator, Junction Box, and Weighing Printer—do not work independently but form a closely coordinated organic whole. The entire workflow of a typical weighing system is as follows: first, when an object is placed on the weighing platform, the load is transmitted to the Load Cell(s), which convert the mechanical load into a weak electrical signal. If multiple Load Cells are used, the Junction Box collects the signals from each Load Cell, adjusts their sensitivity to ensure consistency, and transmits the combined signal to the Weighing Indicator. The Weighing Indicator then amplifies, filters, and converts the analog signal into a digital signal, processes it through the microprocessor to obtain the accurate weight value, and displays it on the screen. Finally, if a permanent record is required, the Weighing Indicator sends the weight data to the Weighing Printer, which prints the relevant information into a document or label. This seamless coordination ensures that the weighing system can quickly, accurately, and reliably complete the weight measurement process and provide actionable data and records.

The application scope of these four core components covers almost all fields that require weight measurement. In industrial production, for example, in the chemical industry, they are used in the batching and filling of raw materials to ensure the accuracy of ingredient proportions, which is crucial for product quality; in the automotive manufacturing industry, they are used in the weighing of auto parts to ensure the safety and reliability of the final product. In logistics and transportation, truck scales and rail scales equipped with these components are used to measure the weight of goods, facilitating the calculation of transportation costs and ensuring compliance with road and rail load limits. In the field of commerce and trade, commercial scales in supermarkets, markets, and logistics centers rely on these components to ensure fair transactions between buyers and sellers. In scientific research, high-precision weighing systems composed of these components are used in laboratories for experiments that require precise weight measurement, such as chemical analysis, material science research, and biological experiments. Even in daily life, such as the weighing of luggage at airports and the weighing of garbage in waste sorting stations, these core components play an indispensable role.

With the continuous development of technology, the four core components of weighing systems are also evolving towards higher precision, intelligence, and integration. In terms of Load Cells, the development of new materials (such as carbon fiber composites) and new sensing technologies is improving their sensitivity, stability, and service life, while reducing their size and weight. Weighing Indicators are becoming more intelligent, with the integration of artificial intelligence and Internet of Things (IoT) technologies, enabling remote monitoring, data analysis, and predictive maintenance of weighing systems. Junction Boxes are moving towards digitization, replacing traditional potentiometers with digital adjustment modules to achieve more precise and automated signal matching. Weighing Printers are also becoming more versatile, supporting wireless communication (such as Wi-Fi and Bluetooth) and integrating with mobile devices and cloud platforms, enabling real-time sharing and management of printed data.

Despite the continuous advancement of technology, the basic role of each core component remains unchanged: the Load Cell is responsible for signal generation, the Weighing Indicator for signal processing and display, the Junction Box for signal convergence and adjustment, and the Weighing Printer for data documentation. The stability and reliability of the entire weighing system depend on the quality of each component and their coordination. Therefore, in the selection, installation, and maintenance of weighing systems, it is crucial to pay attention to the matching of each component. For example, the accuracy class of the Load Cell should match the requirements of the application scenario, the Weighing Indicator should have the appropriate communication interfaces and functions to connect with other components, the Junction Box should be able to accommodate the number of Load Cells used, and the Weighing Printer should be selected according to the printing environment and requirements.

In conclusion, the Weighing Indicator, Load Cell, Junction Box, and Weighing Printer are the four core pillars of modern weighing systems, each with unique and irreplaceable functions. Their close coordination enables the accurate, efficient, and reliable completion of weight measurement tasks, providing strong support for various fields such as industry, logistics, commerce, and scientific research. As technology continues to evolve, these components will continue to be upgraded and optimized, driving the continuous development of weighing technology towards higher precision, intelligence, and integration. Understanding the working principles, functional characteristics, and coordination mechanisms of these core components is not only important for the correct selection and use of weighing systems but also for promoting the innovation and application of weighing technology in more fields.